1.Shorter cycle time,higher productivity and less power consumption

2.Caps produced on hydraulic cap molding machine has no gate tips,smooth on surface,easy for priting.

3.Quality of caps is far more consistent,stable grammage and uniform wall thickness.

4.Cap's weight can be adjusted the minimum grammage possible,lower costs.

5.Molds are easy to assembled and disassembled,quick mold changeover and less down time.

6.Optimized design,user-friendly touch screen control,adjustable speed of production.

|

|

|

|

|

|

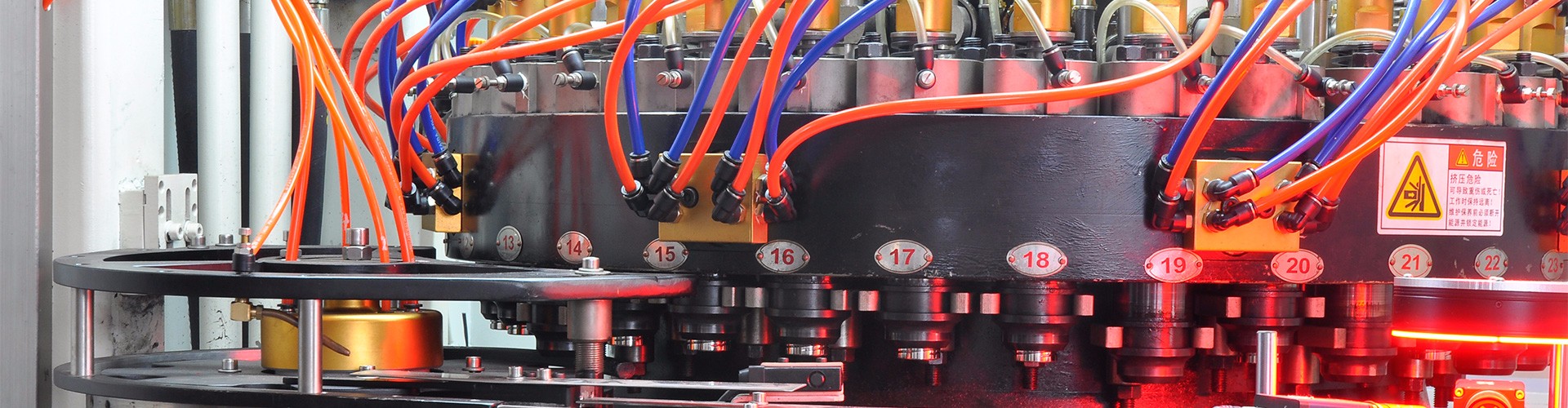

Imported mould material S136 from Sweden and beryllium copper from USA. DLC treatment, no need mould oil. |

|

High and low pressure oil-way distribution direct ejection technology. Oil cylinder and oil pipe are together with machine to be one part. No oil valve and oil leakproof design, machine maintenance is more simple. |

|

Cap made is high density, nice appearance. |

Technical parameters

Model

Mould Number

Cap Diameter

Max. Capacity(pcs/hr.)

Installation Power

Consumed Power

MF-80-24

24

15-60mm

24000-30000

57kw

39kw

MF-80-32

32

42000-45000

64.5kw

45kw

MF-80-48

48

65000-70000

68kw

47kw