MF-50 Normal Speed Cap Molding Machine

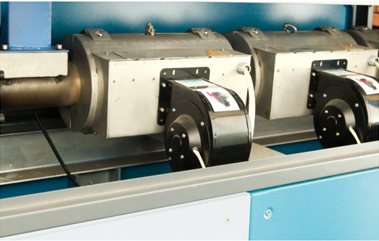

2.Caps produced on hydraulic cap molding machine has no gate tips,smooth on surface,easy for priting.

3.Quality of caps is far more consistent,stable grammage and uniform wall thickness.

4.Cap's weight can be adjusted the minimum grammage possible,lower costs.

5.Molds are easy to assembled and disassembled,quick mold changeover and less down time.

6.Optimized design,user-friendly touch screen control,adjustable speed of production.

|

|

|

|

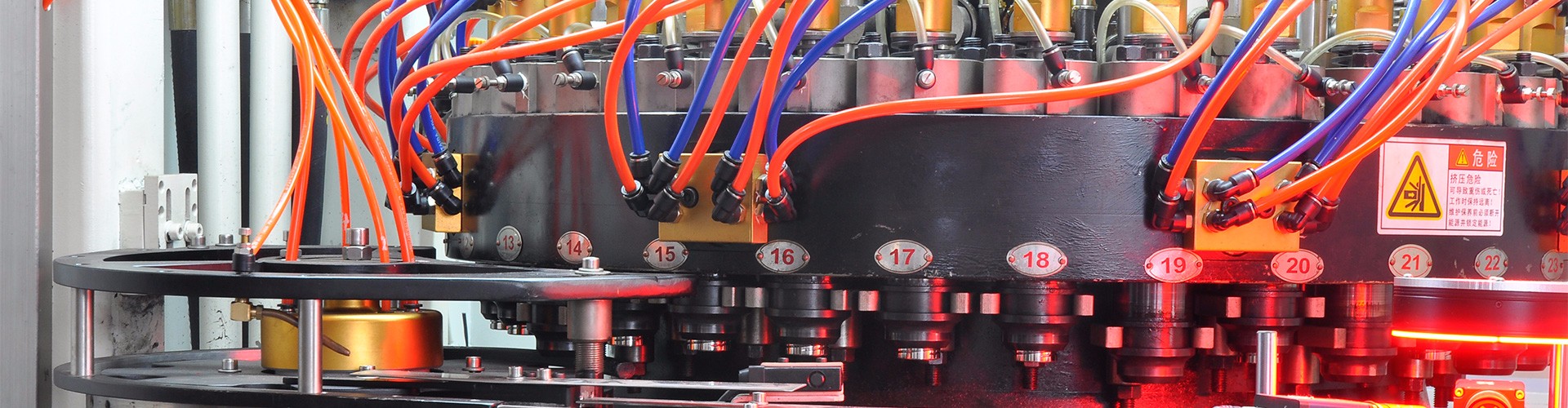

There is automatic control for oil valve going up and down. Mould is easier to be changed and protected well.

|

|

Timing cooling, more stable |

Technical parameters

| Model | Mould Number | Cap Diameter | Max. Capacity(pcs/hr.) | Installation Power | Consumed Power |

| MF-50-18 | 18 | 15-60mm | 17000-18000 | 40kw | 30kw |

| MF-50-24 | 24 | 23000-25000 | 40kw | 30kw | |

| MF-50-32 | 32 | 30000-32000 | 52kw | 42kw |

Send Message